Technological Units

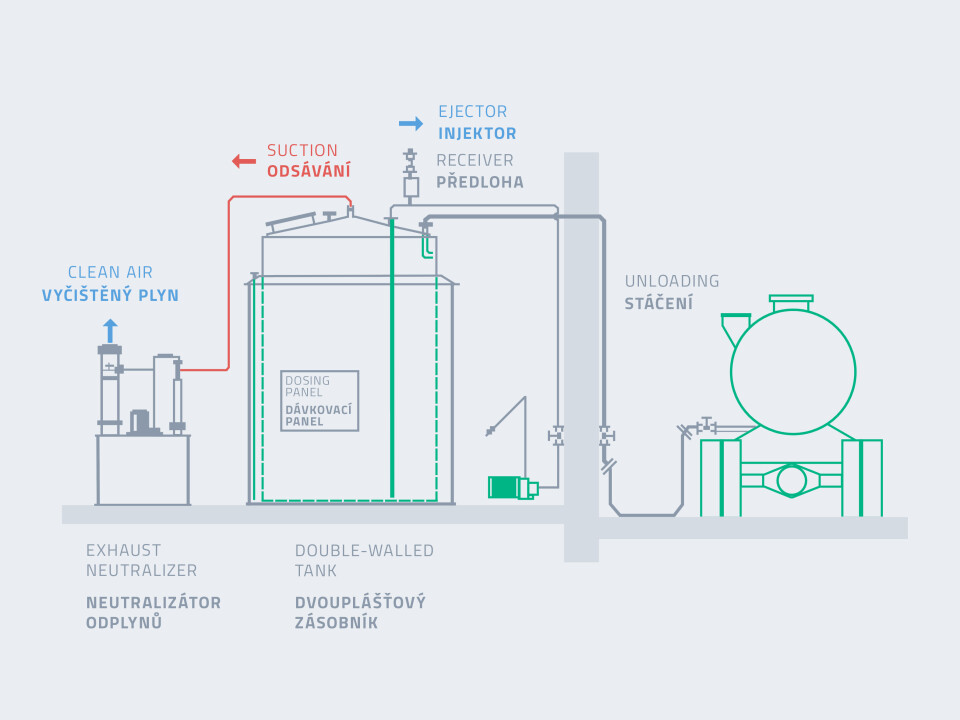

By chemical management we mean the tapping, storage and dosing of chemicals, together with the extraction of odours and the wet cleaning of fumes arising during these activities.

According to the motto of our company "RELIABILITY AND DURABILITY", the basic point of view for the design and project of chemical management is the safety of all elements of chemical management, multiple protection against all potential dangers, especially the impact on the environment.

Personal protective equipment, safety showers and containers for contaminated waste are also included in the "primary equipment" of chemical management.

A significant advantage of plastic devices is the minimal carbon footprint during production and especially during disposal by recycling (melting and reuse).

As operating aggregates and process units, we most often deliver complete units:

- Dilution of sulphuric acid

- Mixing caustic soda

- Dilution of sodium hypochlorite

- Preparation of whitewash

- Mixing flocculants and coagulants

We often design mixing systems as a circulating system with static mixer as a basic unit, or an injector or mixing nozzle.

For the research centres at institutes, chemical companies and universities, ZOMAplast produces complete equipment for semi-operations and experimental facilities.

Pilot assembly options:

- Vessels with mixers, heating or cooling

- Pressurized and non-pressurized vessels

- Dosing and dilution units

- Semi-operational fume extractors

- Laboratory scrubbers of fumes

- Automatic neutralizers of waste solutions