Wet cleaning of fumes by wastewater – Ecological project

PRECHEZA Přerov started The Washing of Fumes with SOx using contaminated waters from own chemical plants. The issue is that it is very final cleaning with efficiency about 90 %.

We obtained the international TÜV quality certificate with the ČSN EN ISO 3824-2 standard.

CertificatesOur company production and assembly programme focuses on chemical engineering, the power industry, and water purification and treatment plants. We are proud to celebrate 30 years of existence with the same company management.

ABOUT THE COMPANY

Tanks made of thermoplastics intended for solutions of aggressive chemical liquids, contaminated waste water,...

Realisation and production of reactors, dilution and dissolution tanks, and pickling and other tanks for surface treatment.

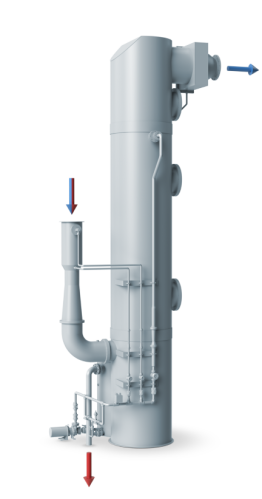

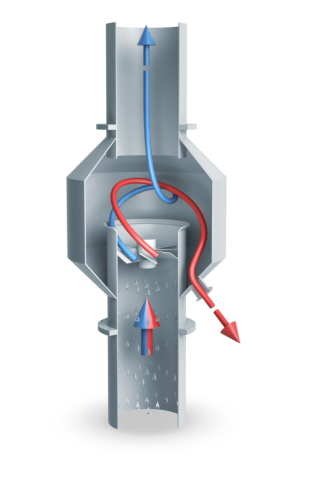

According the type of wet cleaning, Venturi scrubbers and packed scrubbers predominate, followed by jet scrubbers, sieve tray scrubbers, spray scrubbers, and injectors.

According to the size of the droplets, we separate the liquid phase either gravitationally by impacts on a wall, profiles, knitted mesh, or fibre beds.

Considering perfect functionality and especially guarantees, the clients do not ask for a single device, but for an aggregate or turnkey project.

The suggested design is preceded by a chemical-engineering project, respecting the applicable legislation and the specific requirements of the future user. We then "fit" the project with equipment, largely manufactured by ourselves, assemble it on-site, and put it into operation.

Chemical Warehouses, Bottling and Dilution, Dosing into the process

Complete Parts of Production.

Pilot Units, Pilot Productions, Absorption Units.

Basic Chemistry, Water Management, Power Industry, Metallurgy, Petrochemistry, Waste Management